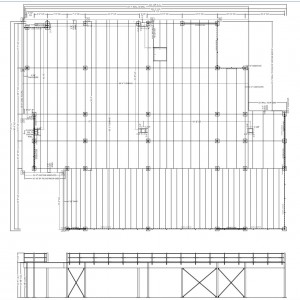

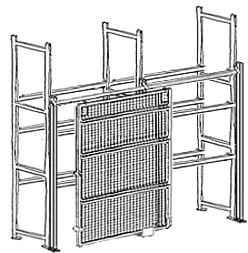

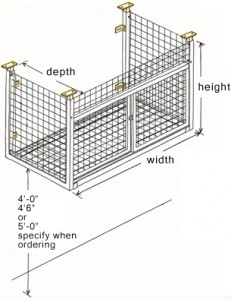

Here’s small photo gallery showing the area where the latest Cogan Mezzanine will be installed in New England. The end user, a lubricant distributor, in central Mass needed to free up some valuable warehouse space. They were storing pallets of empty pails which were taking up the precious floor space needed for finished product. A Cogan Mezzanine is the obvious solution for this application. The vertical space above the filling line was there but couldn’t be used. Once completed, the Cogan Mezzanine will provide storage space for pallets of pails while freeing up valuable floor space for finished product.