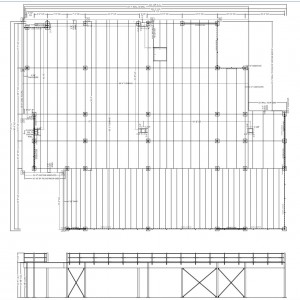

Even at over 7000 square feet this, as with almost every other mezzanine is a game of inches. Trying to install steel in a space that’s already occupied is a BIG problem. Measuring the job is one of, if not the most important phases of a mezzanine job. Prime Alliance Marketing uses the latest in laser technology to assure accurate measurements. We also use our years of experience to scan the job site for obstructions or situations that might not be obvious to the less trained eye, but if not taken into account in the design, will be a problem once the steel starts going up. Stay tuned for more on this Cogan Mezzanine installation. It’s probably the most complex job that we’ve been involved in.

Tag Archives: Cogan Mezzanine

Mezzanines, Even at Over 7000 Square Feet, It’s Still a Game of Inches

Cogan Mezzanine Being Installed at a Graphics Company North of Boston

This Cogan Mezzanine is being installed in a space with a previously installed mezzanine on several sides. The deck height needs to be matched and the deck from the new structure needs to run continuously onto the old structure.

- Columns on the perimeter of the new mezzanine structure need to be placed close to the existing mezzanine’s columns to minimize the impact to traffic patterns.

- The new structure needs to be designed to miss the existing building support columns.

- The new structure needs to extend to the existing structure to allow the new deck to meet the existing deck.

This gallery shows some of the results from challenges that were encountered and designed into the new structure.

Special thanks to Preferred Equipment Resource for going with a Cogan Mezzanine for this job and the expert installation job from Future Installations.

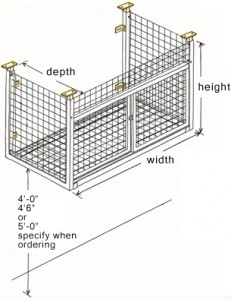

Cogan Econo-Fence Hanging Lockers

This system offers a fully-suspended unit featuring a spacious 6′, 7′ or 8’W x 4’H x 3’D interior. All side floor and transom panels are made of unframed 2″ x 2″ x 6 and 8 GA electro-galvanized welded wire mesh. This innovative design allows for any necessary trimming around water pipes, wall irregularities and other obstructions to be done on-site, eliminating costly installation charges. Slide frames are made of 1 1/2″ x 1 1/2″ x 16GA square tubing and come pre-welded with adjustable ceiling plates for easy adaptability on uneven surfaces. All upper and lower tracks, as well as doors are sealed with a silver powder coated paint finish. All hanging locker systems are equipped with 2 sliding doors. Padlock hasps and door stoppers come standard with all systems. Cogan’s expertise in condo lockers contributes greatly to the success of the easy to order, easy to install storage solution for Condo garages, or and parking garage applications. See the full line of Cogan Condo Lockers here.

This system offers a fully-suspended unit featuring a spacious 6′, 7′ or 8’W x 4’H x 3’D interior. All side floor and transom panels are made of unframed 2″ x 2″ x 6 and 8 GA electro-galvanized welded wire mesh. This innovative design allows for any necessary trimming around water pipes, wall irregularities and other obstructions to be done on-site, eliminating costly installation charges. Slide frames are made of 1 1/2″ x 1 1/2″ x 16GA square tubing and come pre-welded with adjustable ceiling plates for easy adaptability on uneven surfaces. All upper and lower tracks, as well as doors are sealed with a silver powder coated paint finish. All hanging locker systems are equipped with 2 sliding doors. Padlock hasps and door stoppers come standard with all systems. Cogan’s expertise in condo lockers contributes greatly to the success of the easy to order, easy to install storage solution for Condo garages, or and parking garage applications. See the full line of Cogan Condo Lockers here.

Cogan Mezzanine Safety Gate Video

Cogan’s patent-pending safety pivot gate is your safest bet for the frequent loading and unloading of material. Specially designed pivot arms allow the gate to be opened on one side while closed on the other, protecting your employees from dangerous fall accidents. Choose between twelve standard sizes to best suit your needs. All standard Cogan gates are sealed in a powder-coated safety yellow paint finish for maximum visibility. Cogan’s safety pivot gate is a welcome addition to any Cogan

Mezzanine Information

Advantages of Mezzanine Systems

Mezzanine systems add a second or third level inside a facility and thereby double or triple the existing space. Typically, mezzanines are used to create new production, office, storage or assembly space, locker rooms, parts departments, stockrooms, cafeterias, stockrooms, company records storage and work platforms. Mezzanine systems can be installed inside manufacturing and processing plants, warehouses, distribution centers, retail stores, office buildings, industrial plants, hospitals, automotive dealerships, universities, government facilities and more.

Mezzanines allow you to gain the space you need without building a new facility or expanding outward. Think of a mezzanine as the solution that helps you expand within. They can be installed inside any facility that has a ceiling height greater than 15 feet. If you have more than 30 feet of overhead space, a multi-level mezzanine can be built to meet your exact area and height requirements.

Advantages of Mezzanine Systems:

- Help maximize existing plant space.

- Create more square footage without expanding your facility.

- Double or triple the existing space inside your facility.

- Accommodate lighting, sprinkler pipe, HVAC ducts, electrical and computer conduit.

- Can be designed to meet your exact space requirements.

- Can be modified to meet future growth needs and planned expansion.

- Improve inventory management & control.

- Can be customized to fit around existing equipment, buildingcolumns and other obstructions – even around angled and curved walls.

- Often incorporate wide spans & unique column spacing to free up valuable floor space.

- Available in shelving supported, full mat and freestanding designs.

- Integrate with shelving, rack, vertical lifts, carousels, flow rack, in-plant offices, conveyors, more.

- Can be disassembled and moved to another location.

Often times, a mezzanine system provides the best space adding solution – especially when compared to new construction or leased space. Mezzanines save additional energy costs (heat, air conditioning, electricity), save land acquisition costs, save property taxes and insurance premiums and qualify for accelerated tax depreciation (one-time investment).